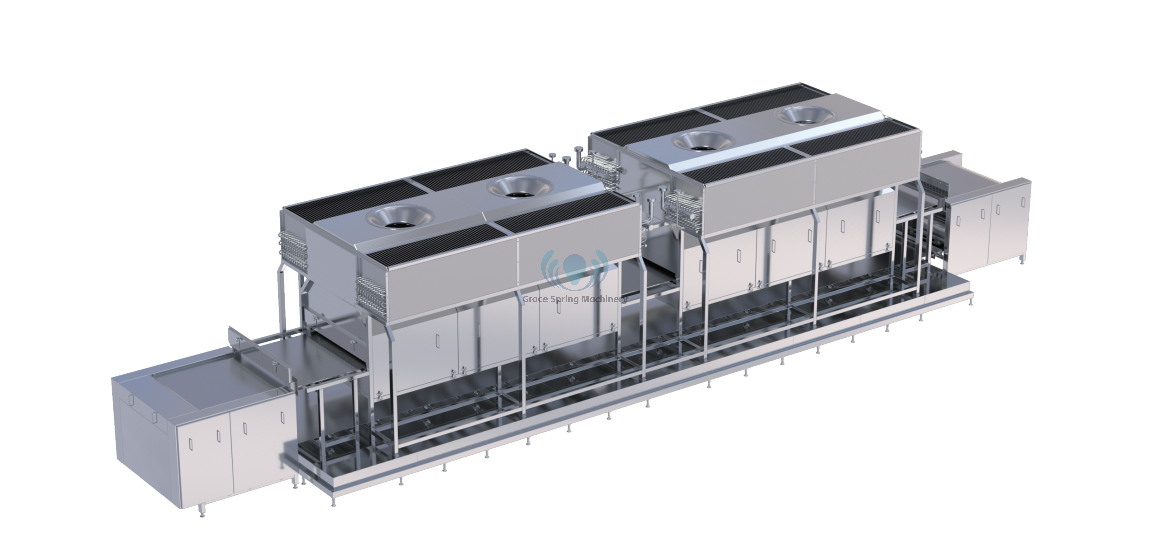

Air Blast IQF Tunnel Freezeris designed as per unique Europe concept.Low temperature airflow circulating inside the enclosure and air tunnel is designed specially.Thousands of high velocity jets of air are directed at the top and bottom surfaces of the product when it moves on conveyor of the freezer.These air jets blast away the boundary layer of air that holds heat around the product,resulting in extremely fast freezing times.

Working Principle

Air Blast IQF Tunnel Freezeris designed as per unique Europe concept.Low temperature airflow circulating inside the enclosure and air tunnel is designed specially.Thousands of high velocity jets of air are directed at the top and bottom surfaces of the product when it moves on conveyor of the freezer.These air jets blast away the boundary layer of air that holds heat around the product,resulting in extremely fast freezing times.

Product Application

The impingement tunnel freezer is especially suitable for the quick freezing of flat food:shrimp products,fish fillets,hamburger patties and other thin food.

Product Features

1.Vertical high-speed impact airflow greatly shortens the freezing time.

2.The surface of food hardens and crusts rapidly to lock in the internal moisture,minimizing the loss of frozen food.

3.Rapid freezing generates no large ice crystals,maintaining the quality of food as much as possible,and keeping it fresh after thawing.

4.Higher freezing efficiency allows for shorter length and smaller equipment space requirement.

5. The fan is placed on the "dry side" of the evaporator to reduce the generation of frost and extend the continuous working time.

6.Modular design is easier for installation and re-allocation,and gives flexibility to expand operation by adding extra modules to the existing ones. 7.All welded stainless steel base plate design: simple structure,easy to clean, make the sanitary conditions easier to meet the requirements.

Technical Specifications

Model | Dimension (mm) | Base Load | Fans Quantity | FreezingCapacity (kg/h) | Belt Width(mm) | Product Height Limit |

JNB-H1208 | 8000×3500×2700 | 25KW | 4 | 250 | 1200 | 标准50mm Standard 50mm |

JNB-H1215 | 15000×3500×2700 | 41KW | 7 | 500 | 1200 | 标准50mm Standard 50mm |

JNT-H500 | 12000×3800×3240 | 29KW | 5 | 500 | 1500 | 标准50mm Standard 50mm |

JNT-H750 | 16000×3800×3240 | 41KW | 7 | 750 | 1500 | 标准50mm Standard 50mm |

JNT-H1000 | 2000×3800×3240 | 52KW | 9 | 1000 | 1500 | 标准50mm Standard 50mm |

JNT-2H750 | 16000×7480×3240 | 82KW | 14 | 1500 | 1500 | 标准50mm Standard 50mm |

Referenced product | Raw dumplings | Infeed temperature: 20°C, Outfeed temperature: -18°C | ||||

JNI-1M1250 | 5500×3500×2970 | 24KW | 2 | 500 | 1250 | 标准35mm Standard 35mm |

JNI-1M1800 | 5500×4000×2970 | 46KW | 3 | 1000 | 1800 | 标准35mm Standard 35mm |

JNI-2M1250 | 11000×3500×2970 | 46KW | 4 | 1000 | 1250 | 标准35mm Standard 35mm |

JNI-3M1250 | 16000×3500×2970 | 68KW | 6 | 1500 | 1250 | 标准35mm Standard 35mm |

Referenced product | Hamburger patty | Infeed temperature: 4°C, Outfeed temperature: -18°C | ||||

Variable | Infeed&Outfeed direction,Tier spacing,Fan quantity Total tiers,Rotation direction,Belt width | |||||

Note: JNl series are all with European technology, advanced technology, equipped with automatic defrosting system. | ||||||

Related Freezer

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat