Industrial food processing demands efficiency, consistency, and scalability. As the food and pharmaceutical industries grow, so does the need for advanced machinery to handle large-scale operations. Jinan Gspring Machinery Co., Ltd, known as Gspring Machinery, is at the forefront of this evolution, offering innovative solutions such as the industrial continuous microwave oven. This article explores how these ovens manage bulk processing, their advantages, and their impact on modern manufacturing.

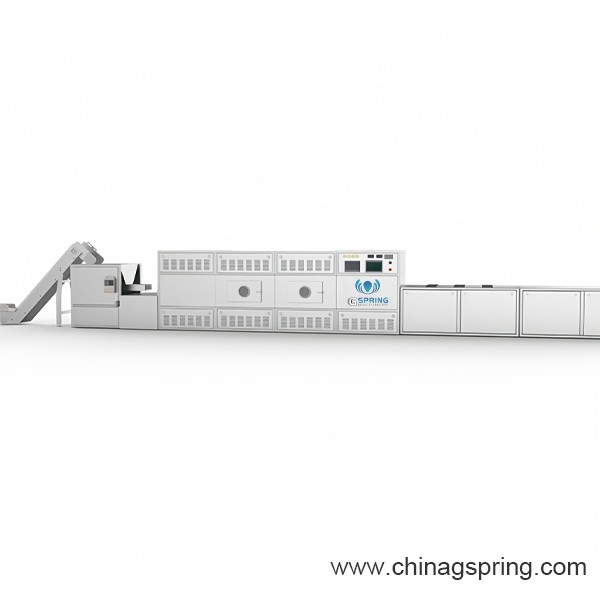

An industrial continuous microwave oven is a high-capacity machine designed to process large quantities of food or pharmaceuticals in a continuous flow. Unlike traditional batch ovens, these machines use conveyor belts to move products through a microwave tunnel, ensuring even and rapid heating. Gspring Machinery has developed advanced models that cater to various industries, including food, pharmaceutical, chemical, and agricultural sectors.

Continuous Processing: Products are fed into one end and exit fully processed on the other, reducing downtime and increasing throughput.

Energy Efficiency: Direct microwave heating reduces energy waste and speeds up processing times.

Uniform Heating: Specially designed cavities and waveguides ensure even distribution of microwaves.

Customizable Settings: Adjustable power, speed, and temperature controls for different products and processing requirements.

Bulk processing is crucial for industries that need to handle large volumes of products efficiently. Whether it’s drying, sterilizing, tempering, or cooking, continuous microwave ovens like those from Gspring Machinery streamline these processes. By automating material handling and reducing manual intervention, these ovens help companies achieve higher productivity and consistent product quality.

Scalability: Enables manufacturers to meet increasing market demands.

Consistency: Ensures uniform product quality across large batches.

Cost Efficiency: Reduces labor and energy costs through automation and direct heating.

For industries such as snack food, pet food, pharmaceuticals, and agricultural products, bulk processing is a game-changer. It allows for continuous production lines, reduces bottlenecks, and enhances the overall supply chain.

Gspring Machinery has engineered its continuous microwave oven systems to address the challenges of bulk processing. Here’s how they excel:

The core of a continuous microwave oven is its conveyor system. Products are loaded onto a belt, which moves them through the microwave chamber at a controlled speed. This ensures each item receives the same amount of energy, resulting in uniform processing.

Operators can fine-tune microwave power and conveyor speed based on product type, size, and desired outcome. For example, delicate pharmaceutical products may require lower power and slower speeds, while robust food items can handle higher settings.

Modern ovens from Gspring Machinery feature sensors and automated controls to monitor temperature, moisture, and processing time. This minimizes human error and ensures products meet strict quality and safety standards.

To accommodate different production scales, Gspring Machinery offers modular ovens that can be expanded or customized. This flexibility allows manufacturers to start small and scale up as demand grows.

Food safety is paramount in bulk processing. The ovens are constructed from stainless steel and feature smooth surfaces, making them easy to clean and maintain. This reduces the risk of contamination and supports compliance with industry regulations.

The versatility of Gspring Machinery’s industrial continuous microwave ovens makes them suitable for a wide array of applications:

Drying: Fruits, vegetables, herbs, spices, and grains can be dried quickly and evenly, preserving flavor and nutrients.

Cooking: Ready-to-eat meals, snacks, and meat products benefit from fast, uniform cooking without over-drying.

Sterilization: Ensures food safety by eliminating bacteria and pathogens.

Sterilization: Medical powders, tablets, and packaging can be sterilized without high temperatures that might degrade active ingredients.

Drying: Reduces moisture content in sensitive materials, improving shelf life and stability.

Pest Control: Microwave energy can eliminate insects and larvae in grains and seeds without using chemicals.

Moisture Reduction: Helps in preparing raw materials for storage and further processing.

A leading snack manufacturer partnered with Gspring Machinery to upgrade their production line. By integrating a continuous microwave oven, they increased throughput by 40% and reduced energy consumption by 25%. Consistent product quality and improved food safety were additional benefits.

| Feature | Benefit |

|---|---|

| Continuous Operation | Maximizes throughput, minimizes downtime |

| Uniform Heating | Ensures product consistency and quality |

| Energy Efficiency | Reduces operational costs |

| Automated Controls | Improves safety, reduces labor |

| Modular Design | Scalable for future growth |

These advantages make Gspring Machinery’s ovens an ideal solution for companies seeking to modernize their production lines and stay competitive in a fast-evolving market.

The food and pharmaceutical industries are rapidly embracing automation to meet growing consumer demands and stringent regulatory requirements. Continuous microwave ovens are a key component of this shift, enabling high-volume production with minimal manual intervention.

Energy consumption and environmental impact are major concerns for modern manufacturers. Gspring Machinery’s ovens use microwave technology that converts electrical energy directly into heat within the product, minimizing energy loss. This not only lowers operational costs but also supports sustainability initiatives.

The rise of Industry 4.0 is transforming traditional factories into smart manufacturing hubs. Gspring Machinery’s ovens can be integrated with digital control systems, enabling remote monitoring, data collection, and predictive maintenance. This reduces downtime, optimizes performance, and enhances traceability.

While continuous microwave ovens offer many benefits, they also present unique challenges:

Product Uniformity: Achieving even heating for irregularly shaped or sized products can be difficult.

Material Compatibility: Some materials may not respond well to microwave energy.

Process Control: Maintaining precise control over temperature and moisture is critical for product quality.

Gspring Machinery addresses these challenges through:

Advanced Waveguide Design: Ensures even microwave distribution throughout the chamber.

Custom Recipe Programming: Operators can save and recall settings for different products.

Integrated Sensors: Real-time feedback allows for instant adjustments to process parameters.

Material Testing Services: Gspring Machinery offers pilot testing to determine the best settings for new products.

As global demand for processed foods and pharmaceuticals continues to rise, the need for efficient, scalable, and sustainable solutions will only grow. Gspring Machinery is investing in research and development to further enhance the capabilities of its continuous microwave ovens, including:

Integration with artificial intelligence for predictive process optimization

Enhanced energy recovery systems for even greater efficiency

Expanded modularity to accommodate new product types and production scales

The future of bulk processing lies in automation, data-driven decision-making, and eco-friendly technologies. Gspring Machinery is committed to leading this transformation.

Bulk processing is essential for modern manufacturing, and the industrial continuous microwave oven is a cornerstone technology that delivers speed, efficiency, and product quality. Gspring Machinery stands out with its innovative designs, robust engineering, and commitment to customer success.

Whether you’re in the food, pharmaceutical, or agricultural sector, investing in a continuous microwave oven from Gspring Machinery means embracing the future of industrial processing. With customizable solutions, industry-leading expertise, and a focus on sustainability, Gspring Machinery is the partner of choice for companies looking to scale up and stay ahead in a competitive market.

For more information on how Gspring Machinery’s solutions can revolutionize your production line, contact their expert team or visit their website to explore the full range of industrial microwave ovens and support services.

industrial continuous microwave oven

continuous microwave oven

Tags:Pharmaceutical Machinery,Gspring Machinery Introduction,Industrial microwave oven manufacturer

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat