In the fast-paced world of industrial processing, efficiency and innovation are the cornerstones of success. Jinan Gspring Machinery Co., Ltd, known in the industry as Gspring Machinery, has been at the forefront of developing advanced drying solutions for various sectors. One of their most revolutionary offerings is the tunnel microwave dryer system, an innovative technology that is transforming the way manufacturers approach drying processes.

The tunnel microwave dryer system utilizes microwave energy to rapidly and uniformly dry materials, offering significant advantages over traditional drying methods. This article delves into the myriad benefits of these systems, explores their applications across industries, and highlights why Gspring Machinery is a trusted name in this field.

A tunnel microwave dryer system is an industrial drying solution that employs microwave technology to remove moisture from products as they pass through a specially designed tunnel. Unlike conventional drying methods that rely on external heat sources, microwave dryers use electromagnetic waves to generate heat within the material itself. This results in faster drying times, improved product quality, and reduced energy consumption.

Efficient Moisture Removal: Microwave energy penetrates deep into materials, ensuring even and thorough drying.

Continuous Operation: The tunnel design allows for continuous processing, making it ideal for high-volume production lines.

Versatile Applications: Suitable for food, pharmaceuticals, chemicals, ceramics, and more.

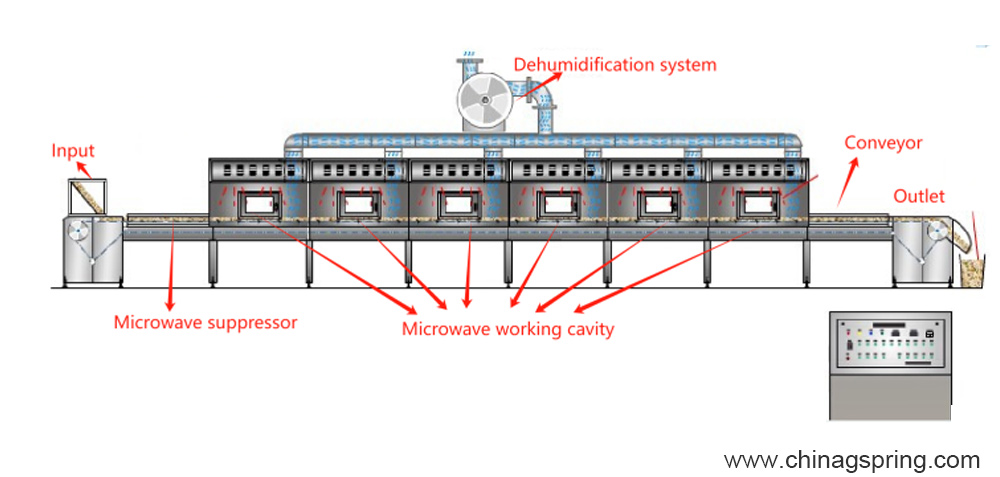

The typical tunnel microwave dryer system from Gspring Machinery includes:

Microwave generator and control system

Conveyor belt for material transport

Insulated tunnel structure

Moisture and temperature sensors

Exhaust and ventilation systems

These components work in harmony to deliver precise drying performance tailored to specific industry needs.

One of the standout advantages of tunnel microwave dryer systems is their ability to dry materials quickly and uniformly. Traditional drying methods often result in uneven moisture distribution, leading to inconsistent product quality. The microwave technology used by Gspring Machinery ensures that energy is evenly distributed throughout the product, reducing drying times and enhancing consistency.

Energy consumption is a major concern in industrial processing. Tunnel microwave dryer systems are designed to be energy-efficient, converting a higher percentage of input energy into useful heat within the product. This leads to significant cost savings over time, as less energy is wasted and operating expenses are reduced.

Microwave drying preserves the physical and chemical properties of materials better than conventional methods. For industries such as food processing, this means retaining essential nutrients, flavors, and textures. In the pharmaceutical sector, it ensures the stability and efficacy of active ingredients.

Modern tunnel microwave dryer systems from Gspring Machinery come equipped with advanced control systems. Operators can monitor and adjust parameters such as temperature, moisture level, and conveyor speed in real-time, enabling precise process control and repeatability.

Reducing energy consumption not only lowers operational costs but also minimizes the environmental footprint of manufacturing processes. Tunnel microwave dryer systems produce fewer emissions and require less auxiliary equipment, such as boilers or fans, further contributing to sustainability goals.

The versatility of tunnel microwave dryer systems makes them suitable for a wide range of industries. Let’s explore some of the key sectors that benefit from this technology:

In food manufacturing, drying is a critical step for products such as fruits, vegetables, grains, meats, and snacks. Tunnel microwave dryers ensure rapid and gentle drying, preserving flavors, colors, and nutrients. Gspring Machinery has supplied systems to food processors seeking to improve throughput while maintaining high product quality.

Precision and hygiene are paramount in pharmaceutical and chemical manufacturing. Tunnel microwave dryers provide a clean, enclosed environment that minimizes contamination risks and allows for precise control over drying parameters. This is essential for sensitive compounds and formulations.

Drying is a crucial step in the production of ceramics, tiles, and other building materials. Traditional drying processes can be slow and energy-intensive. Tunnel microwave dryer systems offer faster drying times and improved product uniformity, reducing defects and increasing production efficiency.

The wood and paper industries also benefit from the rapid, uniform drying provided by microwave technology. This helps prevent warping, cracking, and other defects, leading to higher-quality finished products.

The demand for efficient, eco-friendly drying technologies is on the rise as industries strive to meet stricter regulatory standards and sustainability targets. Tunnel microwave dryer systems are at the forefront of this trend, offering a viable solution for companies looking to modernize their production lines.

Recent advancements in sensor technology, automation, and data analytics have further enhanced the capabilities of tunnel microwave dryers. Gspring Machinery has integrated these innovations into their systems, providing clients with comprehensive process monitoring, predictive maintenance, and remote diagnostics.

IoT Integration: Real-time data collection and analysis for optimized performance

Automated Control: Reduced need for manual intervention and improved process reliability

Customizable Designs: Tunnel microwave dryers can be tailored to specific product requirements and facility layouts

While tunnel microwave dryer systems are ideal for continuous, high-volume operations, another related technology offered by Gspring Machinery is the microwave vacuum dryer. This system combines microwave heating with vacuum pressure, allowing for gentle drying at lower temperatures. It is particularly suitable for heat-sensitive materials, such as pharmaceuticals, nutraceuticals, and specialty foods.

Both tunnel microwave dryer and microwave vacuum dryer technologies exemplify the commitment of Gspring Machinery to providing cutting-edge solutions for diverse drying challenges. By offering both systems, the company can address a broader range of client needs, from rapid bulk drying to delicate, low-temperature applications.

A leading fruit processor partnered with Gspring Machinery to upgrade their drying line. By implementing a tunnel microwave dryer system, they reduced drying times by 60% and improved product consistency. The result was a higher-quality product with better color retention and nutritional value, leading to increased market share.

A pharmaceutical manufacturer specializing in herbal extracts faced challenges with moisture control and product stability. After installing a microwave vacuum dryer from Gspring Machinery, they achieved precise moisture levels and preserved the bioactivity of sensitive compounds, meeting stringent quality standards.

A ceramics company sought to reduce energy consumption and speed up production. With the adoption of a tunnel microwave dryer system, they cut drying times in half and improved product uniformity, resulting in fewer defects and lower operating costs.

With decades of experience and a reputation for innovation, Jinan Gspring Machinery Co., Ltd stands out as a leader in the field of industrial drying solutions. Their tunnel microwave dryer systems are engineered for reliability, efficiency, and adaptability, making them a preferred choice for clients worldwide.

Comprehensive Support: From consultation and design to installation and after-sales service

Customization: Systems tailored to specific industry and product needs

Global Reach: Serving clients across multiple continents

Continuous Innovation: Ongoing R&D to stay ahead of industry trends

Whether you are seeking to upgrade your existing drying processes or embark on a new production venture, Gspring Machinery offers the expertise and technology to help you succeed.

The tunnel microwave dryer system represents a paradigm shift in industrial drying, offering unparalleled speed, efficiency, and product quality. As industries continue to evolve, the demand for advanced drying solutions will only grow. By choosing Jinan Gspring Machinery Co., Ltd as your partner, you gain access to the latest innovations and a team dedicated to your success.

Explore the possibilities of tunnel microwave dryer and microwave vacuum dryer technologies with Gspring Machinery—and take your production processes to the next level.

Ready to discover how a tunnel microwave dryer system can benefit your business? Contact Jinan Gspring Machinery Co., Ltd for a personalized consultation and experience the future of industrial drying.

Tags:Gspring Machinery Introduction,Grinder & Mixer,Industrial microwave oven manufacturer

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat