In the fast-paced world of food manufacturing, maintaining product consistency is not just a quality benchmark—it's a necessity for building a trustworthy brand. For companies producing bread crumbs, the challenge is even more pronounced due to the delicate nature of the product and the stringent demands of the market. Jinan Gspring Machinery Co., Ltd, widely known as Gspring Machinery, has positioned itself as a leader in this field, offering advanced solutions such as the industrial bread crumb machine to help bakeries and food processors achieve unparalleled consistency and efficiency.

Bread crumbs are a staple ingredient across global cuisines, used for coating, binding, and adding texture to a variety of dishes. Inconsistent bread crumb size, texture, or moisture content can negatively impact the final product, leading to customer dissatisfaction and increased waste. Consistency is therefore crucial, not only for the end consumer but also for downstream food manufacturers who rely on uniform ingredients for their recipes.

Traditional bread crumb production often involves manual labor or outdated equipment, resulting in variable quality and inefficiencies. This is where automation and modern technology, like the industrial bread crumb machine from Gspring Machinery, come into play, offering a transformative solution for producers aiming for excellence.

Microwave Machine in Paper Wood and Ceramics

Dough Lifter

Industrial Dough Mixer

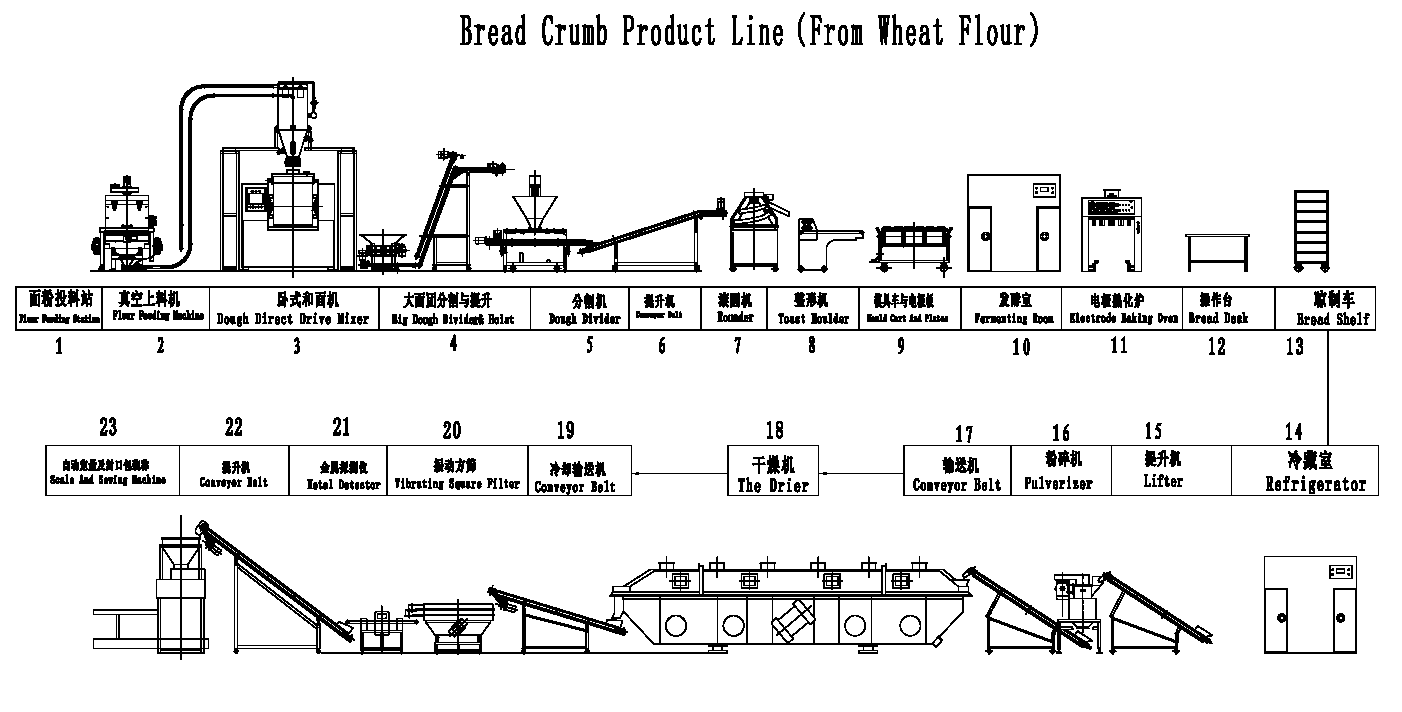

At its core, an industrial bread crumb machine is designed to streamline the entire process of bread crumb production, from grinding and drying to sifting and packaging. These machines are engineered to handle large volumes while maintaining precise control over critical parameters like particle size, moisture content, and uniformity.

Automated Grinding: Ensures bread is broken down into uniform particles.

Consistent Drying: Controls moisture levels for optimal shelf life and texture.

Precision Sifting: Separates crumbs by size for tailored applications.

Integrated Packaging: Reduces contamination and ensures hygienic handling.

By automating these steps, Gspring Machinery’s industrial bread crumb machines eliminate human error and deliver a product that meets strict quality standards every time.

Jinan Gspring Machinery Co., Ltd has invested heavily in research and development to create machines that are not only robust and efficient but also adaptable to the evolving needs of the food industry. Some standout features include:

Adjustable Particle Size: Easily customize crumb size for different culinary applications.

Energy Efficiency: Advanced heating and drying systems minimize energy consumption.

Stainless Steel Construction: Ensures durability and meets food safety regulations.

Automated Controls: User-friendly interfaces and programmable settings enhance operational ease.

Continuous Production: High-capacity output to meet industrial-scale demands.

These features make Gspring Machinery’s equipment a preferred choice for both large-scale bakeries and food processing plants.

Consistency in bread crumb production is directly tied to the technology employed. Modern machines are equipped with sensors and feedback systems that monitor every stage of the process. For instance, the bread crumb production line from Gspring Machinery integrates real-time monitoring to ensure every batch meets preset specifications.

This technological edge is essential for manufacturers who supply to restaurants, fast food chains, and packaged food companies that demand exacting standards. The ability to deliver uniform bread crumbs, batch after batch, translates into fewer product recalls, improved customer satisfaction, and enhanced brand reputation.

The global food processing industry is undergoing rapid transformation, driven by automation, digitalization, and a growing emphasis on food safety. Companies like Gspring Machinery are at the forefront, leveraging these trends to deliver smarter, more reliable equipment. The adoption of industrial bread crumb machines is part of a broader shift towards Industry 4.0, where interconnected devices and data analytics drive efficiency and quality control.

Predictive Maintenance: Sensors detect wear and tear, reducing downtime and maintenance costs.

Data Logging: Detailed records of production parameters aid in traceability and compliance.

Remote Monitoring: Operators can oversee multiple machines from a central control room.

This integration of technology not only enhances consistency but also positions manufacturers to respond quickly to market changes and regulatory requirements.

Adopting an industrial bread crumb machine from Gspring Machinery offers a host of benefits that go beyond consistency:

Increased Throughput: High-speed processing meets growing market demand.

Lower Labor Costs: Automation reduces the need for manual intervention.

Enhanced Food Safety: Closed systems minimize contamination risks.

Waste Reduction: Precise control reduces off-spec batches and raw material loss.

Flexibility: Machines can be quickly reconfigured for different products or recipes.

These advantages are critical in an industry where margins are tight and competition is fierce. Consistency, efficiency, and adaptability are the pillars of long-term success.

A leading bakery in Southeast Asia recently upgraded its production line by installing a bread crumb production line from Gspring Machinery. The results were immediate and impressive: product uniformity improved by over 30%, production speed doubled, and customer complaints related to bread crumb quality dropped to near zero. This case underscores the transformative potential of investing in advanced machinery.

Food safety and regulatory compliance are non-negotiable in today’s market. Gspring Machinery designs its equipment to meet international standards, including HACCP and ISO certifications. This not only protects the end consumer but also gives manufacturers a competitive edge when entering new markets.

Moreover, as consumers become more discerning, they expect transparency and consistency in the products they buy. The use of an industrial bread crumb machine ensures that every package delivered to the shelf meets the highest standards of quality and safety.

Sustainability is another key concern in modern food processing. Gspring Machinery’s bread crumb machines are engineered for energy efficiency and minimal waste. The use of recyclable materials, efficient motors, and optimized heating systems reduces the carbon footprint of the production process, aligning with the growing demand for eco-friendly manufacturing practices.

Selecting the right equipment is a strategic decision that impacts every aspect of production. Gspring Machinery works closely with clients to assess their unique needs, offering customized solutions for different scales of operation and product requirements.

Production Capacity: Machines are available in various sizes to match output goals.

Customization: Adjustable settings cater to specific crumb textures and applications.

After-Sales Support: Comprehensive training, maintenance, and technical assistance.

This partnership approach ensures that clients not only get the best equipment but also ongoing support to maximize their investment.

As the food industry continues to evolve, the demand for consistent, high-quality ingredients will only intensify. Industrial bread crumb machines, such as those offered by Gspring Machinery, are set to play an increasingly vital role in meeting these demands. With ongoing advancements in automation, data analytics, and sustainability, the future of bread crumb production looks brighter than ever.

For food manufacturers seeking to enhance product consistency, reduce costs, and stay ahead of the competition, investing in a state-of-the-art industrial bread crumb machine is not just a smart move—it's essential. Jinan Gspring Machinery Co., Ltd stands ready to help you achieve these goals with cutting-edge solutions tailored to your needs.

In summary, an industrial bread crumb machine is a game-changer for food manufacturers aiming for consistency, efficiency, and quality. With industry leaders like Gspring Machinery driving innovation, the path to superior bread crumb production is clear. Whether you are a small bakery or a multinational food processor, the right technology can elevate your products and your brand to new heights.

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat