Bread crumb production has become an essential part of the food processing industry, especially as the demand for processed foods continues to rise globally. As a leading player in the field, Jinan Gspring Machinery Co., Ltd (hereafter referred to as Gspring Machinery) is at the forefront of technological advancements in bread crumb machine ODM (Original Design Manufacturing). One of the most crucial aspects that determines the efficiency and performance of bread crumb machines is speed optimization. This article delves into how speed optimization impacts bread crumb machine ODM performance and why it is a key consideration for manufacturers and clients alike.

ODM, or Original Design Manufacturing, refers to companies like Gspring Machinery designing and manufacturing machines that are then sold under another company's brand. In the context of bread crumb machines, ODM services allow food processing companies to receive custom-designed equipment tailored to their unique production requirements. This flexibility is vital in a competitive market where product differentiation and efficiency are paramount.

Bread crumb machines are used to process baked bread into fine or coarse particles, which are then used as coatings for fried foods, fillers, or toppings. The efficiency and consistency of these machines directly affect the quality of the final food products. Therefore, optimizing the speed at which these machines operate is crucial for meeting both production quotas and quality standards.

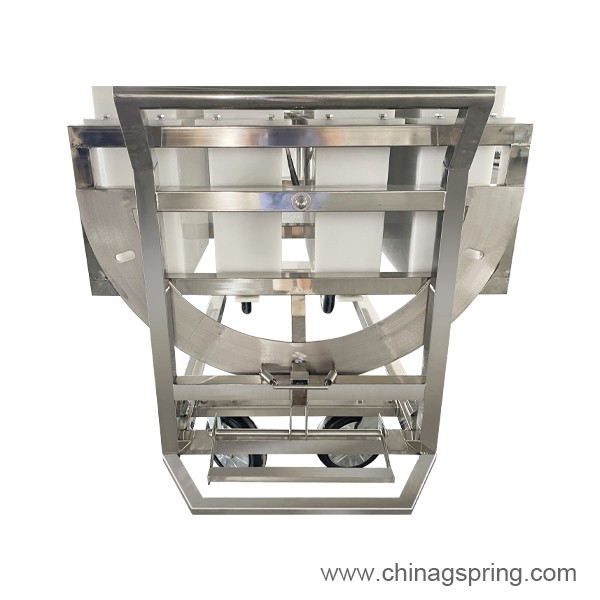

Dough Lifter

Tunnel freezer

Industrial Dough Mixer

Speed optimization involves calibrating the operational speed of bread crumb machines to achieve the best balance between throughput, energy consumption, and product quality. In ODM projects, this means designing machines that can operate at variable speeds, depending on the specific needs of the client. Speed optimization is not just about running machines faster; it is about finding the optimal speed where efficiency, safety, and quality converge.

Throughput: Higher speeds generally increase production output, but may impact product consistency.

Energy Consumption: Running machines at optimal speeds can reduce energy costs and extend equipment lifespan.

Product Quality: Excessive speed might lead to uneven crumb sizes or overheating, affecting the final product.

One of the primary benefits of speed optimization in bread crumb machines is the significant boost in production efficiency. For manufacturers like Gspring Machinery, integrating advanced speed control systems into their ODM bread crumb machines allows clients to maximize output without sacrificing quality. With adjustable speed settings, operators can fine-tune the process to match the specific requirements of different bread types and crumb textures.

Speed optimization ensures that the bread crumb machines process materials uniformly, resulting in consistent crumb sizes and textures. Inconsistent speeds can cause irregularities, such as over-processing or under-processing certain batches. Gspring Machinery’s ODM solutions often feature intelligent control panels that enable real-time speed adjustments, maintaining the desired product quality throughout the production cycle.

Operating bread crumb machines at optimal speeds helps reduce unnecessary energy consumption. Running machines too fast can increase wear and tear, leading to frequent maintenance and higher operational costs. Conversely, too slow a speed reduces throughput and efficiency. Gspring Machinery’s ODM machines are designed with energy-efficient motors and smart sensors that adapt speed according to load and processing conditions, resulting in lower power bills and longer equipment life.

Speed optimization also plays a critical role in ensuring the safety of both operators and equipment. Machines operating at non-optimal speeds are more prone to malfunctions and accidents. Gspring Machinery integrates multiple safety features into their ODM bread crumb machines, including overload protection and emergency stop mechanisms, all of which are calibrated to respond effectively at any operational speed.

The food machinery industry is witnessing rapid advancements in automation and digitalization. Companies like Gspring Machinery are leveraging Industry 4.0 technologies to offer smarter, more connected bread crumb machines. These advancements are tightly linked to speed optimization, as automated systems can monitor and adjust speeds in real-time, responding to fluctuations in input materials or processing requirements.

Automation: Automated bread crumb machines reduce human intervention, improving hygiene and operational consistency. Automation also allows for precise speed control, minimizing human error.

IoT Integration: Internet of Things (IoT) sensors can track machine performance metrics, including speed, load, and temperature. This data is invaluable for predictive maintenance and continuous speed optimization.

Data Analytics: Advanced analytics platforms help manufacturers analyze production data, identify bottlenecks, and fine-tune operational speeds for maximum efficiency.

Gspring Machinery’s latest ODM bread crumb machines are equipped with smart automation features and digital control systems, setting new benchmarks in the industry for efficiency and reliability.

To illustrate the impact of speed optimization, consider a recent ODM project undertaken by Gspring Machinery for a major food processing client. The client required a bread crumb machine capable of handling multiple bread types and producing various crumb textures. Gspring Machinery designed a custom machine with advanced speed control features, including programmable settings for different recipes.

After installation, the client reported a 25% increase in production capacity and a 15% reduction in energy costs, all while maintaining consistent crumb quality. The ability to adjust the speed for different product lines allowed the client to diversify their offerings without investing in multiple machines. This case highlights how speed optimization, when integrated into ODM solutions, delivers tangible business benefits.

When searching for the right equipment, many food manufacturers look for both “bread crumb machine ODM” services and “automatic bread crumb machine” solutions. Gspring Machinery excels in both areas. Their ODM services ensure that each machine is tailored to the specific needs of the client, while their automatic bread crumb machines incorporate the latest automation technologies for seamless operation. By combining ODM customization with automation, Gspring Machinery delivers machines that are not only fast and efficient but also easy to operate and maintain.

The integration of speed optimization into both bread crumb machine ODM and automatic bread crumb machine designs demonstrates Gspring Machinery’s commitment to innovation and customer satisfaction. Whether you need a fully automated production line or a custom-designed machine, speed optimization remains a core feature that sets Gspring Machinery apart in the industry.

As the food processing industry continues to evolve, the demand for customized, high-performance machinery will only increase. Speed optimization will remain a central focus, as manufacturers strive to balance productivity, quality, and sustainability. Companies like Gspring Machinery are leading the way by investing in research and development, ensuring their ODM solutions incorporate the latest advancements in automation, digitalization, and speed control.

Emerging trends such as AI-driven process optimization, remote monitoring, and eco-friendly designs are expected to shape the next generation of bread crumb machines. Gspring Machinery is already exploring these technologies, working closely with clients to deliver machines that are not only fast but also smart and sustainable.

In summary, speed optimization is a pivotal factor that influences the performance, efficiency, and reliability of bread crumb machine ODM solutions. Gspring Machinery’s expertise in integrating advanced speed control systems ensures that their clients receive machines that are tailored to their unique production needs, delivering superior results in terms of output, quality, and cost-effectiveness.

Whether you are seeking a bread crumb machine ODM partner or looking to upgrade to an automatic bread crumb machine, Gspring Machinery’s focus on speed optimization and technological innovation makes them a trusted choice in the global food machinery market. As industry trends continue to evolve, partnering with a forward-thinking manufacturer like Gspring Machinery will help you stay ahead of the competition and achieve your production goals.

For more information about Gspring Machinery’s bread crumb machine ODM services or to learn about their latest automatic bread crumb machine models, visit their official website or contact their sales team. Discover how speed optimization can transform your production line and set new standards in efficiency and quality.

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat