In the ever-evolving world of manufacturing, efficiency and innovation are paramount. Manufacturers are constantly on the lookout for technologies that streamline operations, reduce costs, and improve product quality. One such breakthrough is the industrial continuous microwave oven. Jinan Gspring Machinery Co., Ltd, known as Gspring Machinery, stands at the forefront of this technological revolution, offering state-of-the-art industrial microwave solutions that are reshaping the manufacturing landscape.

Traditional heating and drying methods, such as conventional ovens and hot air dryers, have long dominated the manufacturing sector. However, these methods often come with significant drawbacks—long processing times, uneven heating, and high energy consumption. The introduction of the industrial continuous microwave oven has addressed many of these challenges, offering a more efficient, consistent, and environmentally friendly alternative.

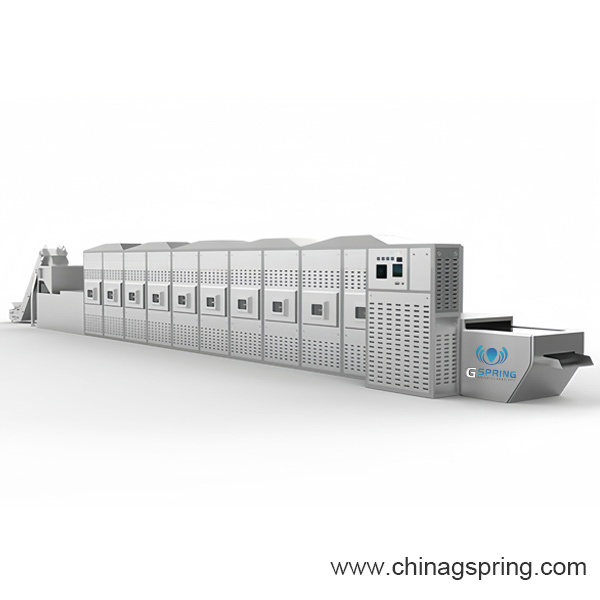

Gspring Machinery has been instrumental in this transformation, leveraging years of experience and innovation to develop microwave ovens that meet the rigorous demands of modern manufacturing. Their industrial continuous microwave ovens are designed for a variety of applications, from food processing to pharmaceuticals and chemicals, ensuring versatility and reliability.

Unlike conventional ovens that rely on conduction and convection to transfer heat, industrial continuous microwave ovens use electromagnetic waves to directly heat the material from within. This results in faster, more uniform heating and drying, significantly reducing processing times and energy consumption.

Gspring Machinery’s continuous microwave ovens are equipped with advanced control systems, allowing precise adjustment of temperature, power, and conveyor speed. This ensures optimal results for a wide range of products, whether it’s drying herbs, sterilizing spices, or curing ceramics.

High Efficiency: Direct microwave heating shortens processing times and increases throughput.

Uniform Heating: Even distribution of microwaves ensures consistent product quality.

Energy Savings: Reduced energy consumption compared to traditional methods.

Precise Control: Advanced automation and control systems for customizable processing.

Environmentally Friendly: Lower emissions and reduced waste.

Versatile Applications: Suitable for food, pharmaceuticals, chemicals, and more.

The versatility of industrial continuous microwave ovens makes them invaluable across numerous sectors. Gspring Machinery has supplied solutions to clients in food processing, pharmaceuticals, chemicals, ceramics, and even wood treatment. Let’s explore some of these applications in detail:

In the food industry, maintaining product quality while ensuring safety and efficiency is crucial. Gspring Machinery’s industrial continuous microwave ovens are used for drying fruits, vegetables, herbs, and spices, as well as sterilizing and pasteurizing finished products. The rapid and uniform heating preserves nutrients, color, and flavor, setting a new standard for food processing.

For pharmaceuticals and chemicals, precise control over temperature and processing time is essential. Gspring Machinery’s microwave ovens provide the accuracy required for drying active ingredients, sterilizing equipment, and processing sensitive materials. The continuous operation allows for high-volume, consistent output, meeting the stringent demands of these industries.

Microwave technology is also revolutionizing the ceramics and building materials industry. By enabling rapid and uniform drying of ceramics, tiles, and bricks, Gspring Machinery’s solutions help manufacturers reduce production cycles and improve product quality.

The integration of continuous microwave ovens in these sectors not only boosts productivity but also aligns with global trends toward sustainability and reduced energy consumption.

The manufacturing industry is undergoing a digital transformation, with automation and smart technologies taking center stage. Gspring Machinery has embraced this shift, incorporating advanced sensors, real-time monitoring, and IoT connectivity into their industrial continuous microwave ovens. These features enable manufacturers to monitor and optimize processes remotely, minimize downtime, and ensure consistent quality.

As the demand for flexible, scalable, and intelligent manufacturing solutions grows, the role of industrial continuous microwave ovens becomes even more significant. By investing in Gspring Machinery’s technology, manufacturers can future-proof their operations and stay ahead of the competition.

With rising energy costs and increasing environmental regulations, sustainability has become a top priority for manufacturers. Industrial continuous microwave ovens from Gspring Machinery are designed with energy efficiency in mind, helping companies reduce their carbon footprint and operating expenses.

By directly heating the product, microwave ovens eliminate the need for excessive preheating and minimize heat loss, resulting in substantial energy savings. This not only benefits the environment but also enhances the bottom line—a win-win for manufacturers.

As the demand for high-performance drying and heating solutions increases, two technologies have emerged as industry favorites: the Industrial Microwave Dryer and the industrial tunnel microwave oven. Both are specialties of Gspring Machinery and offer unique advantages for manufacturers.

An industrial microwave dryer is designed for rapid, uniform drying of bulk materials. Unlike traditional dryers that rely on surface heating, microwave dryers penetrate deep into the material, ensuring even moisture removal. Gspring Machinery’s industrial microwave dryers are used extensively in food processing, pharmaceuticals, and chemical industries, where precision and efficiency are paramount.

Ideal for heat-sensitive products

Reduces drying time by up to 70%

Maintains product quality and integrity

The industrial tunnel microwave oven is a continuous processing system that combines the benefits of microwave heating with conveyor automation. Products move through a tunnel-shaped chamber, where they are exposed to controlled microwave energy. This technology is perfect for high-volume operations, such as drying, sterilizing, or cooking packaged and unpackaged goods.

Continuous, automated operation for high throughput

Customizable tunnel lengths and power levels

Consistent results for every batch

Gspring Machinery’s expertise in both technologies ensures that clients receive tailored solutions that address their specific needs, whether it’s a standalone industrial microwave dryer or a fully integrated industrial tunnel microwave oven.

Selecting the right equipment is critical to maximizing efficiency and return on investment. Gspring Machinery offers a comprehensive consultation process, working closely with clients to assess their production requirements, product characteristics, and facility constraints.

Product Type: Moisture content, density, and sensitivity to heat

Production Volume: Batch or continuous operation

Space Requirements: Available floor space and layout

Energy Consumption: Targeted efficiency and cost savings

Automation Needs: Integration with existing production lines

Gspring Machinery’s team of engineers and technicians ensures seamless installation, commissioning, and after-sales support, making the transition to microwave technology smooth and hassle-free.

Numerous manufacturers have already experienced the transformative impact of Gspring Machinery’s industrial continuous microwave ovens. For example, a leading herbal tea producer reported a 60% reduction in drying time and a significant improvement in flavor retention after switching to a Gspring Machinery microwave dryer. In the ceramics industry, manufacturers have achieved higher yields and reduced defects, thanks to the uniform heating provided by industrial tunnel microwave ovens.

These success stories highlight the tangible benefits of adopting advanced microwave technology—faster production, better quality, and lower operating costs.

As industries continue to embrace automation, sustainability, and digitalization, the role of industrial continuous microwave ovens will only grow. Gspring Machinery is committed to ongoing research and development, ensuring that their products remain at the cutting edge of technology.

Emerging trends such as artificial intelligence, machine learning, and data analytics are being integrated into microwave systems, enabling predictive maintenance, real-time optimization, and adaptive processing. This not only enhances operational efficiency but also provides valuable insights for continuous improvement.

With global supply chains becoming more complex and customer demands more varied, flexibility and adaptability are key. Gspring Machinery’s modular and customizable solutions empower manufacturers to respond quickly to changing market conditions and regulatory requirements.

Choosing the right technology partner is essential for long-term success. Gspring Machinery distinguishes itself through:

Proven Expertise: Decades of experience in industrial microwave technology

Comprehensive Solutions: From consultation to after-sales support

Customization: Tailored systems to meet unique production needs

Innovation: Continuous R&D to stay ahead of industry trends

Global Reach: Trusted by manufacturers worldwide

By partnering with Gspring Machinery, manufacturers gain access to the latest advancements in industrial continuous microwave ovens, backed by a team dedicated to their success.

The industrial continuous microwave oven is more than just a piece of equipment—it’s a catalyst for transformation in modern manufacturing. With faster processing, improved quality, and significant energy savings, it’s no wonder that forward-thinking manufacturers are making the switch.

Gspring Machinery, a leader in microwave technology, offers the expertise, innovation, and support needed to harness the full potential of this game-changing solution. Whether you’re interested in an industrial microwave dryer, an industrial tunnel microwave oven, or a fully integrated system, Gspring Machinery has the answer.

Embrace the future of manufacturing. Discover how Gspring Machinery can help you boost your process, enhance your products, and secure a competitive edge in the marketplace.

Ready to revolutionize your manufacturing process? Contact Gspring Machinery today to learn more about their industrial continuous microwave ovens and discover the solution that’s right for you.

Contact: Grace Guo

Phone: +8617686617441

E-mail: grace@chinagspring.com

Whatsapp:+8617686617441

Add: No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, China, 250000

We chat